Economy

NITI Aayog Report on Chemical Industry

- 05 Jul 2025

- 9 min read

For Prelims: NITI Aayog, Global Value Chains, Chemical Industry, Viability Gap Funding (VGF), Free Trade Agreements (FTAs), PLI Scheme, Extended Producer Responsibility (EPR), Anti-dumping, Carbon Border Adjustment Mechanism (CBAM), MSME.

For Mains: Status and challenges associated with the chemical industry in India, NITI Aayog proposed policy interventions to promote chemical industry.

Why in News?

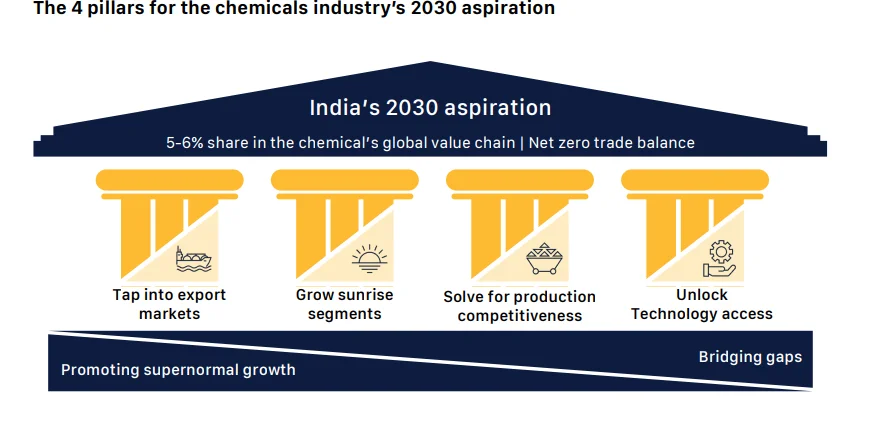

NITI Aayog released its report titled ‘Chemical Industry: Powering India’s Participation in Global Value Chains’, outlining an ambitious roadmap for India to become a global chemical manufacturing powerhouse.

- The report envisions India achieving a 12% share in global chemical value chains (GVC) and a USD 1 trillion output by 2040.

What is the Status of the Chemical Industry in India?

- Global Standing: India ranks as the 6th largest chemical producer globally, contributing over 7% to the manufacturing GDP.

- The chemical sector supports critical industries such as pharma, textiles, agriculture, and construction.

- Feedstock Utilization: India shows over-concentration in bulk chemical production, with 87% of benzene used for alkylbenzene, chlorobenzene, and cumene, unlike the global trend where only 25% is used similarly and more goes to complex derivatives.

- Low Share in Global Value Chains (GVC): India holds only a 3.5% share in global chemical value chains, with a USD 31 billion trade deficit (2023).

- The sector remains fragmented, dominated by MSMEs, with growth concentrated in Gujarat, Maharashtra, and Tamil Nadu.

- Skill and Innovation Gaps: There is a 30% shortage of skilled professionals, especially in green chemistry, nanotechnology, and process safety.

- R&D investment is just 0.7% of industry revenue, well below the global average of 2.3%, limiting innovation in high-value and sustainable chemicals.

- Import Dependence: The sector is heavily import-dependent, sourcing over 60% of critical Active Pharmaceutical Ingredients (APIs) from China, and other feedstocks from Gulf countries.

- Regulatory Bottlenecks: clearances and regulatory delays add to operational costs, with delays of up to 12-18 months for approvals.

What are the Opportunities in India’s Chemical Industry?

- Rising Domestic Demand: India’s consumer and industrial growth is fueling demand in agrochemicals (4th-largest producer), pharmaceuticals (3rd-largest drug producer), and construction & automotive (paints, adhesives, polymers).

- Refinery expansions (e.g., Reliance, Nayara, BPCL) will further boost petrochemical production.

- Job Creation: The sector is expected to generate 7 lakh skilled jobs by 2030, particularly in areas such as petrochemicals, research, and logistics.

- Global Supply Chain Shift: India can capture the shifting global chemical trade from China, especially in dyes & pigments, surfactants, textile chemicals, and electronic chemicals used in semiconductor and EV battery manufacturing.

- Green & Sustainable Chemicals: The global shift toward bio-based and green chemicals is creating demand for bio-plastics, and bio-lubricants where India’s sugar and biomass resources can support the production of bio-based chemicals.

What are the Proposed Policy Interventions by NITI Aayog to Promote Chemical Industry?

- World-Class Chemicals Hubs: Establish hubs by forming an Empowered Committee with a dedicated Chemical Fund for shared infrastructure and Viability Gap Funding (VGF).

- Port Infrastructure: Set up a Chemical Committee for ports and develop 8 high-potential chemical clusters near ports to enhance logistics and export capabilities.

- OPEX Subsidy Scheme: Introduce an OPEX Subsidy Scheme to incentivize incremental production based on import reduction, export potential, single-source dependency, and end-market criticality.

- Develop & Access Technologies: Promote self-sufficiency and innovation by disbursing R&D funds for industry-academia collaboration via DCPC and partnering with MNCs to bridge technological gaps.

- Fast-Track Environmental Clearances: Simplify and expedite Environmental Clearances (EC) through an audit committee under DPIIT to ensure compliance.

- Secure FTAs: Pursue targeted FTAs with tariff quotas and duty exemptions on critical raw materials and feedstocks; improve FTA awareness, origin proof procedures, and export competitiveness.

- Talent & Skill Upgradation: Expand ITIs and specialized training institutes to meet the growing demand for skilled labor, and strengthen industry-academia partnerships for courses in petrochemicals, polymer science, and industrial safety.

India’s Initiatives to Support the Chemical Industry

- Production linked incentive (PLI) Scheme: PLI Scheme for Promotion of Domestic Manufacturing of Critical Key Starting Materials (KSMs), Drug Intermediates and APIs aims to boost domestic production by encouraging the establishment of Greenfield plants.

- PCPIR: The Petroleum, Chemicals and Petrochemicals Investment Region (PCPIR) set up at Paradip has attracted investments worth USD 8.84 billion, resulting in employment of about 40,000 people.

- Jan Aushadhi Kendras: The Government aims to open 25,000 Jan Aushadhi Kendras to ensure affordable access to medicines.

What Steps are Needed to Strengthen the Chemical Industry?

- Global Integration: Sign Mutual Recognition Agreements (MRAs) to align Indian chemical standards with global norms, and establish a dedicated chemical export promotion council for market access and brand building.

- Strengthen Safety Standards: Enforce strict safety norms and implement real-time monitoring systems in chemical clusters to enhance safety and compliance.

- Promote green and sustainable chemistry through waste recycling, low-emission processes, and incentivize adoption of zero liquid discharge (ZLD) and clean production technologies.

- Financial & Investment Support: Ease access to capital by offering lower interest loans to MSME chemical manufacturers and promoting venture capital funding for specialty chemical startups, while ensuring risk mitigation through subsidized insurance.

- Skill Development: Upskill the workforce through industry-aligned chemical engineering courses focusing on process safety and green technology.

- Enhance safety protocols by mandating Process Safety Management (PSM) audits and enforcing the Chemical Accidents Rules, 1996 more strictly.

Conclusion

India’s chemical industry, a GDP growth driver, aims to become a global manufacturing hub by 2030 through policy interventions like chemical hubs, OPEX subsidies, FTAs, and an R&D push. Overcoming import dependency, regulatory hurdles, and sustainability challenges requires global integration, safety enforcement, green chemistry, and skill development to achieve USD 1 trillion market potential.

|

Drishti Mains Question: Q. Discuss the status, challenges, and policy measures required to make India a global leader in the chemical industry. |

UPSC Civil Services Examination, Previous Year Questions (PYQs)

Prelims

Q. In India, ‘extend producer responsibility’ was introduced as an important feature in which of the following? (2019)

(a) The Bio-medical Waste (Management and Handling) Rules, 1998

(b) The Recycled Plastic (Manufacturing and Usage) Rules, 1999

(c) The e-Waste (Management and Handling) Rules, 2011

(d) The Food Safety and Standard Regulations, 2011

Ans: (c)