Agriculture

Ethanol Production

- 28 Jun 2024

- 14 min read

For Prelims: Curb on Sugar Diversion for Ethanol, Ethanol Blended Petrol (EBP), Biofuels, Feedstocks, Crude Oil Import, Food Security, Global Biofuel Alliance

For Mains: Ethanol Production, Indian Economy, and issues relating to planning, mobilization of resources, growth, development, and employment.

Why in News?

Recently, India has achieved higher ethanol production from grains, particularly maize, surpassing that from sugar-based feedstock.

What is Ethanol?

- About:

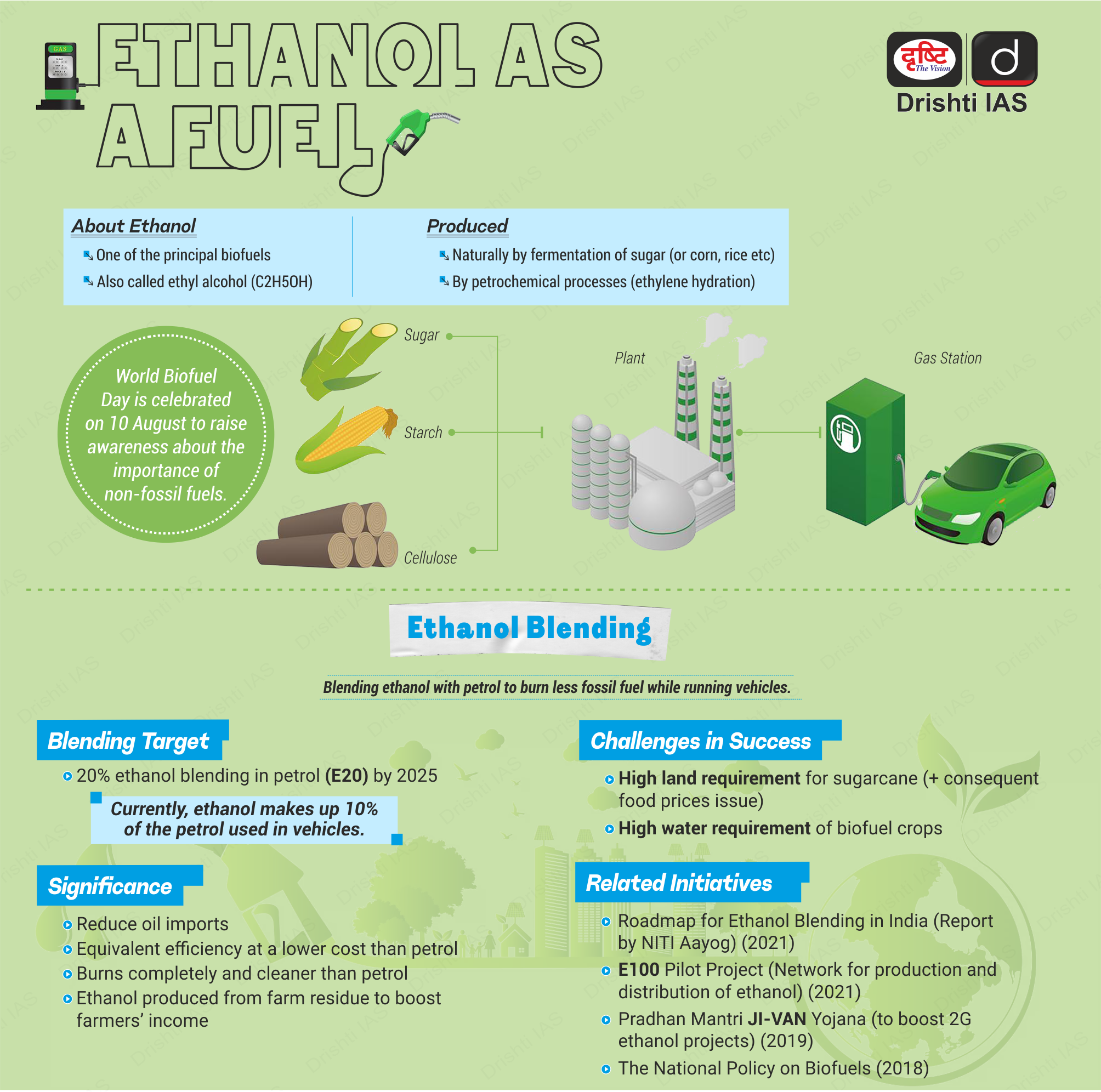

- Ethanol, also known as ethyl alcohol, is a biofuel produced from various sources such as sugarcane, corn, rice, wheat, and biomass.

- Molasses, a byproduct of sugar manufacture, are generally the main source of production of ethanol (anhydrous alcohol) and rectified spirit. Molasses can be categorised into following:

- A Molasses (First Molasses): An intermediate by-product from initial sugar crystal extraction, containing 80-85% dry matter (DM).

- B Molasses (Second Molasses): Similar DM content as A molasses but with less sugar and no spontaneous crystallization.

- C Molasses (Final Molasses, Blackstrap Molasses, Treacle): The end by-product of sugar processing, containing significant amounts of sucrose (about 32 to 42%). It does not crystallize and is used as a commercial feed ingredient in liquid or dried form.

- The production process involves the fermentation of sugars by yeasts or via petrochemical processes such as ethylene hydration.

- Ethanol is 99.9% pure alcohol that can be blended with petrol to create a cleaner fuel alternative.

- Properties of Ethanol:

- Ethanol is a clear, colorless liquid with a characteristic wine-like odor and pungent taste.

- It is fully soluble in water and most organic solvents.

- In its pure form, it has a boiling point of 78.37 degrees Celsius and a melting point of -114.14 degrees Celsius.

- Ethanol is a combustible material and has a lower combustion temperature than gasoline, making it a cleaner-burning alternative.

- Applications of Ethanol:

- Beverages: Ethanol is the type of alcohol found in alcoholic beverages. It is consumed socially in various forms, such as beer, wine, and spirits.

- Industrial Solvent: Due to its ability to dissolve a wide range of substances, ethanol is used as a solvent in the manufacturing of pharmaceuticals, perfumes, and other products.

- Medical and Laboratory Uses: Ethanol is used as an antiseptic, disinfectant, and preservative in medical and laboratory settings.

- Chemical Feedstock: It serves as a feedstock for the production of various chemicals.

- Fuel: It is used as a biofuel and is often mixed with gasoline to produce ethanol-blended fuels.

What are the Measures to Promote Ethanol Production?

- Feedstock Diversification: Ethanol production in India was mainly based on 'C-heavy' molasses, with a sugar content of 40-45%, yielding 220–225 litres of ethanol per tonne.

- Earlier, India explored direct sugarcane juice for ethanol production, increasing yield and efficiency.

- However, India is using other methods also for increasing production. The country has diversified its feedstocks by including rice, damaged grains, maize, jowar, bajra, and millets.

- It has been seen that Ethanol yields from grains are higher compared to molasses, with rice producing 450-480 liters and other grains 380-460 liters per tonne.

- By 9 June 2024, India produced 3.57 billion litres of ethanol.

- Out of this, 1.75 billion litres were from sugar-based feedstock (sugarcane juice, B-heavy molasses, C-heavy molasses) and 1.81 billion litres were from grain-based feedstock with maize alone contributing 1.10 billion litres.

- Grain-based ethanol now constitutes nearly 51% of the total ethanol production for the current ethanol-supply year (November 2023-October 2024).

- The National Agricultural Cooperative Marketing Federation of India Ltd (NAFED) and the National Cooperative Consumers' Federation of India Ltd (NCCF) are procuring maize to promote its use in ethanol production.

- It has been seen that Ethanol yields from grains are higher compared to molasses, with rice producing 450-480 liters and other grains 380-460 liters per tonne.

- Moreover, Leading sugar companies have installed distilleries that can operate on multiple feedstocks such as rice, damaged grains, maize, and millets throughout the year for continuous production.

- Government's Differential Pricing Policy: The government has fixed different prices for ethanol derived from C heavy molasses, B heavy molasses, sugarcane juice/sugar/sugar syrup, and damaged food grains or rice.

- For example, from 2018-19, the Indian government began fixing higher prices for ethanol produced from B-heavy molasses and whole sugarcane juice/syrup.

- This policy has helped increase the supply of ethanol for the Ethanol Blended Petrol (EBP).

- E20 fuel is a blend of 20% ethanol and 80% petrol. The E20 was launched by the Prime Minister of India in February 2023 in Bengaluru.

- This pilot covers at least 15 cities and will be rolled out across the country in a phased manner.

- Setting up Ambitious Targets:

- India has set up a very ambitious target to increase Ethanol production in the country. For Instance, India plans to start using 20% ethanol blended petrol (E20) from 2025.

- As of 9 June 2024, India achieved a 12.7% ethanol blend with petrol, targeting 15% for the current year.

- Achieving the E20 target by 2025-26 will require 10.16 billion litres of ethanol, according to NITI Aayog estimates.

- India has set up a very ambitious target to increase Ethanol production in the country. For Instance, India plans to start using 20% ethanol blended petrol (E20) from 2025.

- International Commitments:

- At the 64th International Sugar Organization meeting, India reaffirmed the commitment to achieving 20% ethanol blending by 2025-26, predicting that grain-based ethanol production will exceed sugar-based ethanol in the 2023-24 supply year.

- In September 2023, India, the US, the UAE, and Brazil launched the Global Biofuel Alliance. The countries agreed to provide financial and technical support to national programmes to promote the sustainable production and use of biofuels.

- Other Policies:

What are the Benefits and Challenges of Ethanol Production?

- Benefits:

- Reduced Dependence on Oil Imports: India imports a significant portion of its crude oil needs. A NITI Aayog report estimates that a successful ethanol blending program can save the country billions of dollars annually by reducing this reliance.

- Boost to Agricultural Income: Increased ethanol production creates demand for crops like sugarcane and grains used in fermentation. This can lead to higher income for farmers according to a report by the International Renewable Energy Agency (IRENA).

- Greenhouse Gas Reduction: Ethanol absorbs carbon dioxide during its production, offsetting combustion emissions and supporting India's carbon footprint reduction goals.

- Job Creation: The ethanol blending program has the potential to generate millions of jobs in rural areas. New distilleries, expanded sugarcane cultivation, and associated logistics will require a significant workforce, boosting the rural economy.

- Waste Management Solution: The ethanol production can utilize molasses that often creates waste disposal challenges. By converting molasses into ethanol, the program promotes a more sustainable approach to waste management within the sugar sector.

- Benefitting from the By products of Ethanol Production: Apart from being a fuel additive, ethanol production yields valuable byproducts like Distillers' Dried Grain with Solubles, and Potash from Incineration Boiler Ash that find applications across various industries.

-

Distillers' Dried Grain with Solubles (DDGS):

- DDGS is a byproduct of grain-based ethanol production.

- It is the residue left after the starch in grains is fermented and ethanol is extracted.

- DDGS is a valuable animal feed with high protein content and is used to supplement livestock diets.

- Potash from Incineration Boiler Ash:

- The ash remaining after Ethanol Production in the boiler contains up to 28% potash.

- This ash is a rich source of potash and can be utilized as a fertilizer.

-

- Challenges:

- Food vs. Fuel: A major challenge is the competition for feedstocks between food production and ethanol production. According to the Environmental Protection Agency (EPA), corn-based ethanol production can lead to increased food prices and even contribute to deforestation in countries pressured to cultivate more land for crops.

- Land and Water Use: Large-scale ethanol production, particularly from corn, requires significant amounts of land and water. This can strain resources and lead to issues like soil erosion and depletion of freshwater supplies.

- Limited Environmental Benefit: While touted as a renewable fuel, the lifecycle greenhouse gas emissions of corn ethanol can be comparable to gasoline, especially when considering indirect land-use changes.

- Costly Processing: The current methods for processing feedstocks, particularly non-food crops like switchgrass, often require energy-intensive treatments to convert them into usable sugars for fermentation.

- Infrastructure Challenges: Ethanol has a higher water content than gasoline, which can lead to corrosion in pipelines and storage tanks.

- Shortage of Raw Material: Though India has planned to achieve Ethanol Blending by 2025 but it often finds raw material shortage for ethanol production. For Example, due to a lower production of sugarcane, the government in December 2023 banned the use of cane juice and B-heavy molasses for ethanol production.

Way Forward

- Promoting Second-Generation (2G) Ethanol Technologies: The potential of 2G technologies using agricultural waste like straw and bagasse for ethanol production can be harnessed to reduce competition for food crops and promote sustainability.

- India can leverage Global Fuel Alliance to develop and provide its members with technology that is both technically feasible and economically viable for producing ethanol from agricultural waste.

- Developing Alternative Feedstocks and Crop Diversity: India can emulate Brazil's ethanol success by using non-food crops like sorghum and miscanthus to diversify feedstock and enhance food security.

- Financial Incentives for Biomass Cultivation and Farmer Integration: The World Bank reports emphasize the need for financial incentives, contract farming models, and guaranteed buyback programs to encourage farmers to cultivate dedicated biofuel crops and ensure a steady feedstock supply.

- Investing in Research and Development for Improved Efficiency: Focusing on advancements in technologies like cellulosic ethanol production, along with increased research funding and international collaboration, can significantly improve ethanol yields.

- Strengthening Infrastructure and Streamlining Logistics: Data from government reports points to the need for significant investments in storage facilities and transportation networks for ethanol.

- Public-private partnerships and innovative logistics solutions can ensure efficient distribution and program scalability.

|

Drishti Mains Question: Q. Discuss the various measures India has taken to achieve its E20 program. Highlight the challenges associated with this initiative. |

UPSC Civil Services Examination, Previous Year Question (PYQ)

Prelims:

Q. According to India’s National Policy on Biofuels, which of the following can be used as raw materials for the production of biofuels? (2020)

- Cassava

- Damaged wheat grains

- Groundnut seeds

- Horse gram

- Rotten potatoes

- Sugar beet

Select the correct answer using the code given below:

(a) 1, 2, 5 and 6 only

(b) 1, 3, 4 and 6 only

(c) 2, 3, 4 and 5 only

(d) 1, 2, 3, 4, 5 and 6

Ans: (a)

Q. Given below are the names of four energy crops. Which one of them can be cultivated for ethanol? (2010)

(a) Jatropha

(b) Maize

(c) Pongamia

(d) Sunflower

Ans: (b)