Indian Economy

BioCNG Production from Dung

- 14 Mar 2024

- 8 min read

For Prelims: Biogas, BioCNG, GOBARdhan, SATAT Scheme

For Mains: Biogas Energy and its Significance, BioCNG, Bioenergy, Related Initiatives

Why in News?

Banaskantha District Co-operative Milk Producers’ Union, Gujarat are converting dung into Bio CNG (compressed natural gas) and fertiliser, supplementing farmers' income. This initiative addresses waste management while creating new revenue streams for dairy farmers.

- The BioCNG outlet on the Deesa-Tharad highway in Gujarat's Banaskantha district is a pioneering initiative, being India's first and only gas-filling station operating on dung sourced from cattle and buffaloes.

How are Farmers Harnessing the Value of Dung?

- Dung Facts:

- An average adult bovine animal discharges 15-20 kg of fresh dung daily, while calves give out 5-10 kg.

- A bovine refers to a domestic animal of the species Bos taurus (cattle) or Bubalus bubalis (water buffalo).

- Fresh dung contains 80-85% water; one kg weighs hardly 200 grams on drying.

- Fresh dung contains methane along with water, making it essential for biogas production in anaerobic digestion (breaks down biodegradable material without oxygen and produces biogas).

- Methane, a key component of biogas, is produced in the rumen of bovines (the first of four stomach compartments in bovines) during the fermentation of plant material they consume.

- Bacteria-like microbes in the rumen, known as archaea, utilise carbon dioxide and hydrogen produced during carbohydrate fermentation to generate methane.

- An average adult bovine animal discharges 15-20 kg of fresh dung daily, while calves give out 5-10 kg.

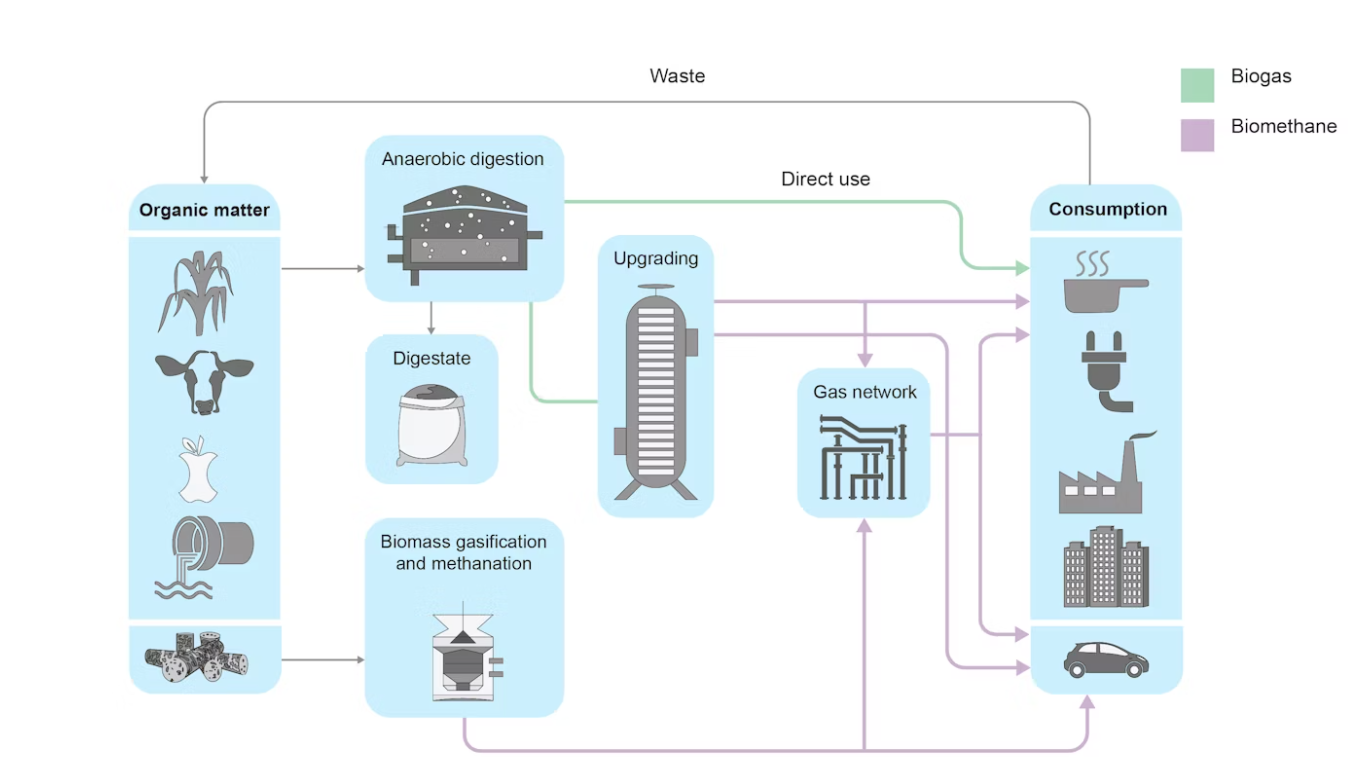

- Biogas Production Process:

- Fresh raw dung is mixed with water in equal quantities to form a slurry. The slurry undergoes anaerobic digestion in a sealed vessel reactor over 35 days.

- The digestion involves four successive stages: hydrolysis (break-down of organic matter into simple molecules), acidogenesis (their conversion into volatile fatty acids), acetogenesis (production of acetic acid, CO2 and hydrogen) and methanogenesis (biogas generation).

- Biogas digesters reduce methane emissions from animal waste, which can help mitigate greenhouse gas impact.

- A single cow can emit between 150 to 260 pounds of methane per year. With over 1.5 billion cattle raised globally for meat and milk production, the industry is responsible for an estimated 14.5% of global human-caused greenhouse gas emissions.

- Fresh raw dung is mixed with water in equal quantities to form a slurry. The slurry undergoes anaerobic digestion in a sealed vessel reactor over 35 days.

- Biogas Purification and Compression:

- Raw biogas is purified to remove CO2, H2S, and moisture through various processes.

- The purified biogas, compressed to 96-97% methane, is stored and farmers sell it as BioCNG at Rs 72/kg.

- Utilization of Slurry for Fertilizer Production:

- After biogas production, the slurry undergoes dewatering in a solid-liquid separator.

- The separated solid residue is decomposed aerobically and sold as PROM (phosphate-rich organic manure) by incorporating rock phosphate and phosphate-solubilizing bacteria.

- Alternatively, the decomposed solid residue can be used for compost production by adding neem and castor cake, sugarcane press mud, and microbial consortia.

- The liquid part is reused for mixing in the digester or sold as liquid-fermented organic manure.

- After biogas production, the slurry undergoes dewatering in a solid-liquid separator.

- Scalability and Replicability:

- The BioCNG model is replicable and scalable, utilising dung from district member unions.

- Gujarat's Kaira Union's decentralised model involves installing Flexi Biogas plants, targeting 10,000 installations.

- Individual farmers benefit from smaller Flexi plants for personal use and potentially generate additional income.

- Whether through large-scale BioCNG plants or smaller decentralized models, the potential for additional income from dung utilization is growing.

Biogas

- Biogas is a renewable energy source that's produced when organic matter breaks down in the absence of oxygen. This process is called anaerobic digestion.

- Biogas is also known as renewable natural gas (RNG) or biomethane. It's made up of mostly methane (CH) and carbon dioxide (CO2).

What are the Key Challenges that Need to be Addressed?

- Feedstock Management:

- Ensuring a consistent supply and quality of organic feedstock for animals.

- Implementing effective waste segregation and collection systems.

- Operational Efficiency:

- Individual farmers and smaller cooperatives might lack the knowledge and resources for proper maintenance and monitoring of BioCNG plants.

- Training programs and readily available technical support and establishing standardised operating procedures and quality control measures are crucial.

- Individual farmers and smaller cooperatives might lack the knowledge and resources for proper maintenance and monitoring of BioCNG plants.

- Technical and Financial Barriers:

- Access to financing options like subsidies, grants, or low-interest loans can help overcome initial capital barriers for setting up BioCNG plants.

- Technical challenges, such as a lack of skilled labour and infrastructure, can be addressed through public-private partnerships, technology transfer, and capacity-building programs.

- Storage Systems for Biogas:

- BioCNG needs to be stored and distributed efficiently to reach end-users, whether for cooking, heating, or electricity generation.

- Proper storage systems, such as gas holders or cylinders, are required to ensure a consistent supply of BioCNG.

- BioCNG needs to be stored and distributed efficiently to reach end-users, whether for cooking, heating, or electricity generation.

- Social Acceptance:

- Overcoming the misconception that dung gas is unhygienic and unsafe is essential for widespread adoption.

- Educational outreach and showcasing the hygienic process are key to promoting decentralised biogas models among rural farmers.

What are India's Initiatives Related to Biogas?

- Sustainable Alternative Towards Affordable Transportation" (SATAT) Scheme

- GOBARdhan

- National Biogas Programme:

- The Ministry of New and Renewable Energy (MNRE) is supporting the installation of biogas plants and its use as a source of alternative fuels for cooking purposes in the country, including rural areas, under the National Biogas Programme.

- Under this scheme, MNRE is providing Central Financial Assistance (CFA) for setting up of biogas plants, ranging from Rs. 9800/- to Rs. 70,400/- per biogas plant based on the size of the plant (1-25 cubic meter/day plant capacity).

UPSC Civil Services Examination, Previous Year Questions (PYQs)

Prelims:

Q. Consider the following: (2019)

- Carbon monoxide

- Methane

- Ozone

- Sulphur dioxide

Which of the above are released into the atmosphere due to the burning of crop/biomass residue?

(a) 1 and 2 only

(b) 2, 3 and 4 only

(c) 1 and 4 only

(d) 1, 2, 3 and 4

Ans: (d)

Mains:

Q. What are the impediments in disposing the huge quantities of discarded solid waste which are continuously being generated? How do we remove safely the toxic wastes that have been accumulating in our habitable environment? (2018)