Facts for UPSC Mains

Indigenous Solar Value Chain

- 15 Sep 2025

- 7 min read

Why in News?

The Ministry of New and Renewable Energy is formulating a plan to create a fully indigenous solar manufacturing ecosystem by 2028, encompassing modules, cells, wafers, and ingots.

What is the Solar Manufacturing Value Chain?

- About: The solar manufacturing value chain encompasses the complete process of converting raw materials into a fully functional solar photovoltaic (PV) module.

- It is a sequential workflow and the chain is generally divided into Upstream (high-tech, capital-intensive) and Downstream (labor-intensive) segments.

- Key Stages:

- Upstream Manufacturing (The Core Components):

- Polysilicon: The process begins with metallurgical-grade silicon derived from quartz sand, which is then processed into polysilicon.

- Ingots: The polysilicon is melted and crystallized into large, cylindrical blocks called ingots.

- Wafers: Ingots are sliced into ultra-thin, disc-shaped sheets using a wire saw. These sheets, called wafers, are the fundamental building block of a solar cell.

- Solar Cell: The wafers undergo doping (adding phosphorus and boron to form an electric field), printing (metal contacts for electron flow), and anti-reflective coating to minimize light reflection. The result is a solar cell capable of converting sunlight into electricity.

- Downstream Manufacturing (Assembly & Installation):

- Module Manufacturing: Solar cells are interconnected, laminated, sealed between glass and polymer back sheets, and framed to form a solar module.

- System Installation & Integration: Modules are assembled into arrays, connected to inverters, mounting structures, and wiring, and installed on rooftops, fields, or solar farms.

- Upstream Manufacturing (The Core Components):

- Current Status: India's solar module capacity has already touched 100 GW, but solar cell capacity is only 27 GW, while ingot and wafer capacity is just 2.2 GW, making it heavily reliant on imports, particularly from China.

- India aims to finalize a roadmap for Swadeshi polysilicon production in the coming years.

- Proposed Reforms: A key step is the proposed expansion of the Approved List of Models and Manufacturers (ALMM), currently for modules, to include solar cells, wafers, and ingots.

- ALMM mandates that solar project developers purchase equipment from approved models and manufacturers, promoting domestic manufacturing and acting as a non-tariff barrier to low-quality or import-dependent products.

What are the Challenges in Developing the Indigenous Solar Value Chain?

Mnemonic: HURDLE

- H – High-Cost & Scale Issues: Indian-made components are initially expensive and less competitive due to dis-economies of scale (business's cost per unit increases instead of decreasing as it expands production).

- U – Upstream Infrastructure Gaps: Polysilicon and wafer manufacturing is technology-intensive and capital-heavy, with limited domestic experience.

- R – RoW & Land Bottlenecks: Land acquisition and Right of Way (RoW) issues block projects.

- D – Delayed Power Purchase Agreements (PPAs): Procurement delays by States/Discoms hurt project viability.

- L – Lack of Experience: Limited experience in advanced solar manufacturing.

- E – Export/Import Dependence: Reliance on imports increases vulnerability.

Achievements in Solar Energy

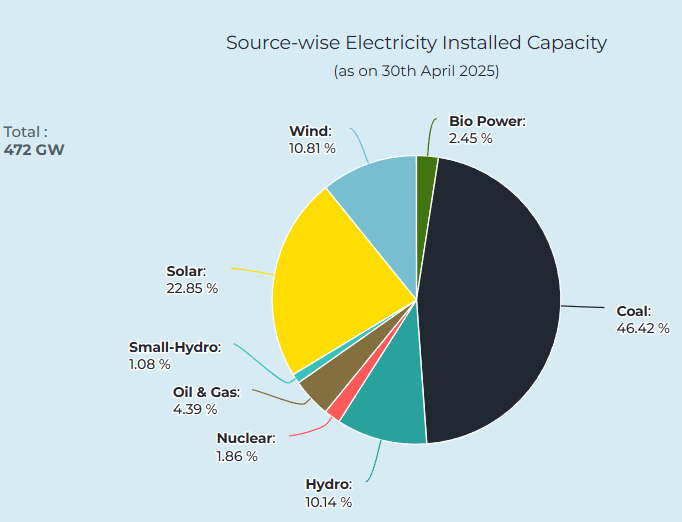

- Renewable Energy: India surpasses 251.5 GW non-fossil energy capacity, achieving over half of its 2030 target of 500 GW.

- PM Suryaghar Yojana: India has already installed 20 lakh rooftop solar projects under the PM Suryaghar Yojana, with expectations to cross 50 lakh installations soon.

- PM-KUSUM scheme: Under the PM-KUSUM scheme, over 1.6 million solar pumps have been installed or solarised, reducing diesel use by 1.3 billion litres annually and cutting CO2 emissions by 40 million tonnes.

What Steps are Needed to Develop a Indigenous Solar Value Chain in India?

- Mnemonic: SHINE

- S – Sustained Policy Support: Expand ALMM, ensure stable PLI, phased customs duties, and clear technology acquisition plans.

- H – Harness Investment: Build Greenfield manufacturing, provide capital support, and resolve land/RoW issues.

- I – Innovation & R&D: Promote next-generation technologies like Perovskite and strengthen ancillary industries.

- N – Navigate Coordination: Streamline state-level execution, ensure Discom financial stability, and align with schemes like PM Suryaghar Yojana and PM-KUSUM.

- E – Expand Demand: Drive domestic solar manufacturing demand through policy and deployment programs.

Conclusion

India’s green energy transition is crucial to achieving net-zero by 2070, with targets of 1,800 GW renewable capacity by 2047 and 5,000 GW by 2070. An integrated roadmap is needed: develop domestic solar manufacturing, resolve land and RoW bottlenecks, fast-track PPA signings, and institutionalize ALMM for wafers, ingots, and polysilicon, enhancing energy security, sustainability, and India’s global solar leadership.

|

Drishti Mains Question: Q. Discuss the challenges in establishing indigenous solar manufacturing and measures to overcome them. |

UPSC Civil Services Examination, Previous Year Questions (PYQs)

Prelims

Q. Consider the following statements: (2016)

- The International Solar Alliance was launched at the United Nations Climate Change Conference in 2015.

- The Alliance includes all the member countries of the United Nations.

Which of the statements given above is/are correct?

(a) 1 only

(b) 2 only

(c) Both 1 and 2

(d) Neither 1 nor 2

Ans: (a)

Mains

Q. India has immense potential for solar energy though there are regional variations in its developments. Elaborate. (2020)