Indian Economy

Reimagining India's Manufacturing Future

- 04 Jun 2025

- 21 min read

This editorial is based on “Manufacturing is crying out for a reality check” which was published in The Livemint on 04/06/2024.The article brings into focus the global challenges in reviving manufacturing amid automation and China's overproduction woes. It emphasizes that India should pursue a diversified growth model, leveraging its strengths in services and skilled workforce alongside manufacturing.

For Prelims: Manufacturing, Make in India, Gati Shakti, Industry 4.0, National Green Hydrogen Mission, World Bank’s Logistics Performance Index 2023, Ease of Doing Business rankings, National Infrastructure Pipeline, Right to Fair Compensation and Transparency in Land Acquisition, Rehabilitation and Resettlement Act, 2013

For Mains: Key Drivers of Growth for India's Manufacturing Sector, Factors Limiting Manufacturing Sector’s Contribution to India’s Economic Growth

The global push to revive manufacturing jobs faces challenges as automation reduces labor requirements, while countries like China struggle with overproduction and financial inefficiencies in sectors like electric vehicles. For India's manufacturing sector, this global experience offers crucial lessons as the country seeks to balance industrial growth with employment generation. India's path to sustainable industrial growth lies not in replicating China's manufacturing-heavy model, but in developing a diversified economy that combines production capabilities with the nation's natural advantages in services and skilled workforce development.

What are the Key Drivers of Growth for India's Manufacturing Sector?

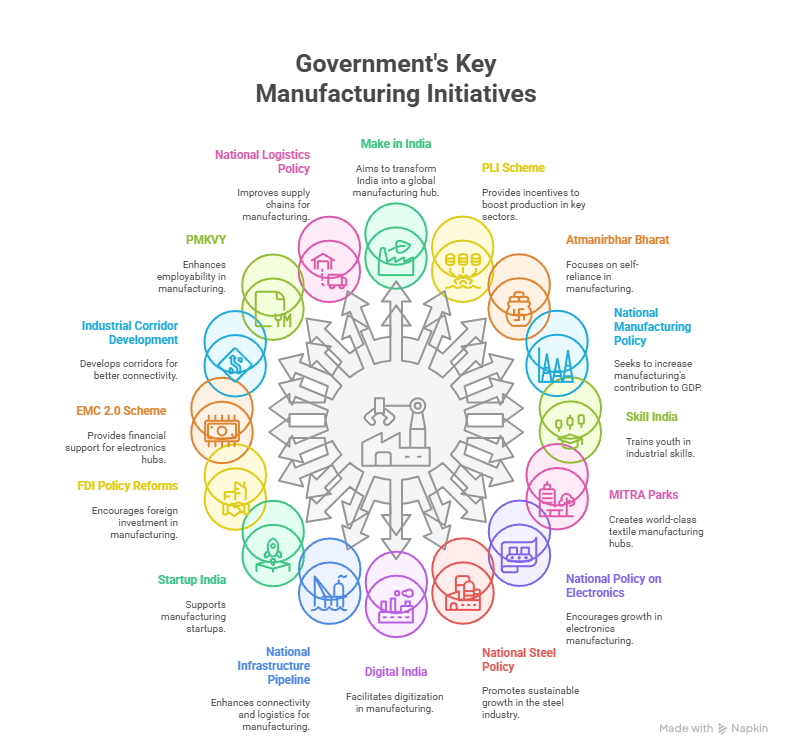

- Policy Support and Government’s Push: India's government has made substantial efforts to boost manufacturing through schemes like the Production Linked Incentive (PLI) and Atmanirbhar Bharat Abhiyan.

- These policies encourage investment and capacity building in sectors like electronics, textiles, and semiconductors.

- The PLI scheme alone has attracted investments of over INR 1.03 lakh crore by November 2023.

- Moreover, foreign direct investment (FDI) inflows in the manufacturing sector grew by 69% from 2014-2024, demonstrating the positive impact of policy reforms.

- Demographic Dividend and Labor Force: India’s large, youthful labor force is a crucial driver for the growth of labor-intensive sectors like textiles and apparel.

- With a working-age population of 900 million, the country has a competitive edge in global markets.

- For instance, the textile and garment sector employs nearly 45 million people, providing significant employment opportunities.

- Additionally, the growth of the gig economy, expected to reach 230 million workers by 2030, adds further dynamism to manufacturing.

- Technological Advancements and Smart Manufacturing: The adoption of Industry 4.0 technologies like AI, IoT, and automation is enhancing productivity and reducing costs in India’s manufacturing sector.

- Companies are increasingly integrating automation technologies to stay competitive.

- For example, Larsen & Toubro and Siemens have implemented AI-driven production systems to improve quality and reduce cycle times.

- India leads globally in manufacturing technology investment, signaling a shift towards advanced production techniques.

- Export Growth and Global Supply Chain Integration: India's expanding role in global supply chains, particularly in sectors like electronics, pharmaceuticals, and automotive, is a major driver of manufacturing growth.

- The rise of the China+1 strategy has led many global companies to shift their production to India.

- For instance, Apple’s production in India reached $14 billion in 2023, marking a significant increase.

- Global firms like Siemens, Micron, and Tesla have increased investments, strengthening India's position in high-tech manufacturing

- Additionally, India’s manufactured exports surged to $450 billion in 2023-24, with key sectors like pharmaceuticals and electronics driving much of the growth.

- Infrastructure Development and Logistics Efficiency: The government’s focus on improving infrastructure, such as industrial parks, logistics hubs, and smart cities, is pivotal for manufacturing growth.

- The National Infrastructure Pipeline (NIP) aims to invest $1.4 trillion into infrastructure over the next decade.

- For instance, Gujarat has become a top destination for manufacturing with a 45% contribution to its GDP from manufacturing, aided by robust infrastructure and logistical advantages.

- Domestic Market Growth and Consumption Demand: The rise of India’s middle class and increasing domestic consumption is a significant driver for manufacturing, especially in sectors like consumer goods, automobiles, and electronics.

- India’s GDP growth at 6.4% in FY 2024-25 supports the potential for domestic demand-driven manufacturing growth.

- With India set to become the 3rd-largest consumer market by 2026, it presents a promising avenue for manufacturers to cater to growing domestic demand.

- Sustainability and Green Manufacturing: India's emphasis on sustainable manufacturing practices is becoming a crucial driver for growth.

- Policies promoting clean energy and electric vehicles (EVs), alongside a commitment to the National Green Hydrogen Mission, are reshaping the sector.

- The electric vehicle (EV) market alone is expected to contribute $1 billion in exports by 2025, driven by increasing demand for green technologies and sustainable products globally.

What Factors Are Limiting Manufacturing Sector’s Contribution to India’s Economic Growth?

- Inadequate Infrastructure and Logistical Challenges: Poor infrastructure and logistical bottlenecks severely restrict the efficiency of India's manufacturing sector.

- Despite the National Infrastructure Pipeline (NIP) targeting $1.4 trillion investments, issues in road, rail, and port connectivity persist.

- India in the logistics performance index ranks 38th globally (2023), far behind China and Vietnam.

- These infrastructure inefficiencies increase manufacturing costs by 20-30%, making it difficult for India to compete with nations like Vietnam, which offers more efficient logistics systems.

- Regulatory Complexity and Bureaucratic Hurdles: India’s manufacturing sector faces significant challenges due to complex regulations and a burdensome compliance framework.

- Despite reforms, bureaucratic inefficiencies continue to hinder growth. For example, the Ease of Doing Business ranking, though improved to 63rd in 2020, still lags behind regional competitors like Malaysia.

- The constant policy changes and delays in approvals from state and central authorities further increase operational costs for manufacturers, impacting global competitiveness.

- Skill Gap and Labor Shortages: The shortage of skilled labor is a persistent issue that limits the productivity and growth of India’s manufacturing sector.

- Despite initiatives like Skill India, there remains a significant mismatch between the skills required by industries and those available in the labor market.

- India's Graduate Skill Index 2025 reveals that only 42.6% of Indian graduates are employable.

- India’s labor productivity in manufacturing remains much lower than that of China. In sectors like textiles and automotive, skilled labor is in short supply, preventing manufacturers from scaling efficiently.

- Despite initiatives like Skill India, there remains a significant mismatch between the skills required by industries and those available in the labor market.

- High Energy Costs and Inadequate Power Supply: High energy costs and unreliable power supply hinder the competitiveness of Indian manufacturers.

- Compared to regional competitors, India’s energy prices are 10-60% higher.

- Recent data states that India's industrial electricity tariffs will average nearly ₹8/kWh in 2025, with costs expected to rise.

- The combination of high energy expenses and the frequent instability of power supply exacerbates the situation, making it difficult for industries to operate efficiently.

- Dependence on Imports and Lack of Domestic Innovation: India's manufacturing sector remains overly dependent on imports, especially for critical raw materials and high-tech components.

- The automobile industry is a prime example, where a large portion of parts and materials are still imported.

- Also, India's semiconductor imports reached ₹1.71 lakh crore in FY24.

- FDI in the manufacturing sector surged by 69% over the last decade, yet India’s R&D expenditure on manufacturing remains low, at just 0.64% of GDP, compared to China’s 2.4%.

- This lack of indigenous innovation limits long-term industrial self-sufficiency.

- The automobile industry is a prime example, where a large portion of parts and materials are still imported.

- Land Acquisition Issues and Expensive Real Estate: Land acquisition remains a major bottleneck for manufacturing growth in India, with cumbersome processes and land acquisition laws causing delays in factory establishment.

- The Right to Fair Compensation and Transparency in Land Acquisition, Rehabilitation and Resettlement Act, 2013 (LARR Act) was introduced to address these issues by ensuring fair compensation and a transparent process.

- However, its implementation has faced criticism for being cumbersome and time-consuming, deterring investment and slowing down project implementation.

- Moreover, high land prices and limited availability of affordable land in industrial zones increase the cost of setting up manufacturing units.

- For instance, Maharashtra, despite being an industrial hub, faces land-related issues that slow down industrial development.

- The Right to Fair Compensation and Transparency in Land Acquisition, Rehabilitation and Resettlement Act, 2013 (LARR Act) was introduced to address these issues by ensuring fair compensation and a transparent process.

- Environmental Regulations and Sustainability Constraints: While the shift to sustainable manufacturing is essential, stringent environmental regulations often create additional compliance costs for manufacturers.

- Despite initiatives like Make in India and PLI schemes, the stringent environmental standards in India create barriers for manufacturers.

- In sectors like textiles, compliance with pollution control norms increases production costs by approximately 15-20%.

- These regulations, though crucial for long-term sustainability, burden small and medium-sized enterprises (SMEs) particularly, limiting their scalability.

- Global Competition and Declining Share in Global Manufacturing: India’s share in global manufacturing remains low compared to leading countries like China and Vietnam.

- With China controlling 31% of global manufacturing, India’s share is only 2.87%.

- This gap has widened due to India’s slower adoption of cutting-edge manufacturing technologies like automation and AI.

- While India’s Manufacturing PMI of 57.6 in May 2025 indicates positive growth, it lags behind more competitive nations, putting its manufacturing ambitions at risk in an increasingly globalized market.

- External Market Vulnerabilities and Trade Policy Risks: India's manufacturing sector is increasingly vulnerable to external shocks, such as trade disruptions, tariff hikes, and geopolitical tensions.

- For instance, the US-China trade war (tariff escalation) led many companies to shift production to India, but protectionist policies in major markets like the US and Europe pose risks for Indian exporters.

- With India's export growth stagnating at $450 billion in FY 2023-24, rising trade barriers and fluctuating global demand limit the sector's ability to grow in international markets.

What Measures India Can Adopt to Enhance the Productivity and Sustainability of the Manufacturing Sector?

- Promote Smart Manufacturing and Digital Transformation: India must accelerate the adoption of Industry 4.0 technologies, including AI, IoT, and automation, to modernize manufacturing processes.

- By integrating smart sensors, predictive maintenance, and real-time data analytics, manufacturers can increase efficiency and reduce operational costs.

- Establishing technology hubs and incentivizing public-private partnerships (PPPs) in advanced manufacturing will help small and medium-sized enterprises (SMEs) adopt digital technologies at scale.

- Strengthen Skill Development with Industry-Specific Training Programs: Bridging the skill gap is essential for enhancing manufacturing productivity. India should create sector-specific training institutes in collaboration with industry leaders to address the evolving needs of the manufacturing sector.

- These institutes should focus on advanced manufacturing techniques, robotics, and sustainable production methods to ensure a workforce ready for the next generation of industrial growth.

- Streamline Regulatory Processes for Ease of Doing Business: A critical measure is the simplification of India’s regulatory framework to reduce compliance costs and delays.

- Implementing a single-window clearance system for all industrial permits, aligning state and central regulations, and reducing the complexity of labor laws can create a smoother environment for manufacturers.

- A national policy for expedited approval processes in key sectors like electronics, textiles, and automotive will help improve the ease of setting up new factories, fostering greater investment.

- Develop Robust Industrial Clusters and Infrastructure: Establishing integrated industrial clusters and logistics hubs with modern infrastructure will significantly enhance manufacturing efficiency.

- These clusters should have access to shared utilities, skilled labor, and logistics networks, fostering collaboration and economies of scale.

- By focusing on creating greenfield industrial zones with adequate water, power, and transportation facilities, India can reduce the cost and time needed to establish new manufacturing plants, attracting both domestic and foreign investments.

- Incentivize Research and Development in Green Technologies: India must intensify efforts to innovate and invest in sustainable manufacturing practices.

- Providing fiscal incentives such as tax rebates and R&D grants for the development of green technologies can help the industry transition towards environmentally friendly production.

- Integrating renewable energy sources and waste-to-energy solutions within industrial zones will promote both sustainability and cost savings.

- Additionally, policies should focus on promoting eco-labeling and green certification programs to encourage the adoption of eco-friendly practices

- Implement a National Strategy for Circular Economy: A circular economy framework can help India build a more sustainable manufacturing sector by encouraging waste reduction, reuse, and recycling of materials.

- A national strategy focused on resource recovery, closed-loop supply chains, and waste minimization will not only enhance sustainability but also reduce costs and dependency on raw materials.

- Manufacturers should be incentivized to develop closed-loop systems and engage in eco-design that minimizes environmental impact throughout the product lifecycle.

- Foster Innovation Ecosystems and Startup Incubators: India should focus on fostering a culture of innovation by developing startup incubators and innovation clusters within industrial zones.

- Supporting startups in sectors like additive manufacturing (3D printing), robotics, and bio-manufacturing can help create cutting-edge technologies and new business models in manufacturing.

- Linking these startups with established manufacturers will allow for a continuous flow of innovation, driving productivity and competitiveness in the global market.

- Align Manufacturing with Export Competitiveness through Trade Agreements: Strengthening India’s export-oriented manufacturing by aligning it with international free trade agreements (FTAs) is a key measure.

- India can enhance its market share in the global economy by utilizing duty-free access to key markets and improving standards compliance through trade agreements.

- Moreover, ensuring that manufactured goods meet international quality standards and certifications will open up more opportunities in high-demand global sectors, boosting manufacturing productivity.

Conclusion:

India’s manufacturing sector stands at a crucial juncture, balancing the need for growth with employment generation and sustainability. Leveraging key initiatives like PLI, fostering a tech-driven ecosystem, and expanding export capabilities are pivotal for future success. With a clear focus on innovation and strategic policy alignment, India can emerge as a competitive manufacturing hub globally while fostering inclusive economic growth.

|

Drishti Mains Question: Examine the key drivers and challenges of India’s manufacturing sector. Suggest measures to enhance its productivity and global competitiveness |

UPSC Civil Services Examination, Previous Year Questions (PYQs)

Prelims

Q. In the ‘Index of Eight Core Industries’, which one of the following is given the highest weight? (2015)

(a) Coal production

(b) Electricity generation

(c) Fertilizer production

(d) Steel production

Ans: (b)

Mains

Q.1 “Industrial growth rate has lagged behind in the overall growth of Gross-Domestic-Product(GDP) in the post-reform period” Give reasons. How far are the recent changes in Industrial Policy capable of increasing the industrial growth rate? (2017)

Q.2 Normally countries shift from agriculture to industry and then later to services, but India shifted directly from agriculture to services. What are the reasons for the huge growth of services vis-a-vis the industry in the country? Can India become a developed country without a strong industrial base? (2014)