India’s Path to Manufacturing Excellence

This editorial is based on “Govt must bite the bullet on land reforms to ease manufacturing growth” which was published in Business Standard on 21/08/2025. The article brings into picture the bottlenecks of land acquisition and pending labour reforms that hinder India’s manufacturing growth, stressing the urgent need for factor market reforms to realise the vision of Viksit Bharat 2047.

For Prelims: Confederation of Indian Industry, Make in India, Production Linked Incentive Scheme, Industry 4.0, Labor codes, Tariffs by the US, Free Trade Agreements

For Mains: Key Recent Developments Shaping India’s Manufacturing Sector, Key Issues Associated with India’s Manufacturing Landscape.

India's manufacturing growth faces a critical bottleneck in land acquisition, where fragmented records, multiple authorities, and unclear titles create costly delays that deter investors. The Confederation of Indian Industry has proposed comprehensive reforms including a GST Council-like land coordination body and integrated state authorities, but political consensus remains elusive. Beyond land issues, pending reforms like the four labour codes further constrain India's manufacturing potential at a time when global supply chains are reshaping. As India aspires for Viksit Bharat 2047, reimagining the manufacturing sector through decisive factor market reforms has become an economic imperative that cannot be delayed.

What are the Key Recent Developments Shaping India’s Manufacturing Sector?

- Surge in Foreign Direct Investment (FDI): India's manufacturing sector has seen a significant surge in foreign direct investment (FDI), solidifying its position as a global investment magnet.

- The growth in FDI enhances domestic capabilities and brings in cutting-edge technologies.

- FDI in manufacturing has reached USD 165.1 billion, marking a 69% increase over the past decade.

- In the last 5 years, India's manufacturing sector saw Rs. 33.58 lakh crore (US$ 383.5 billion) in total FDI inflows, highlighting robust confidence from global investors.

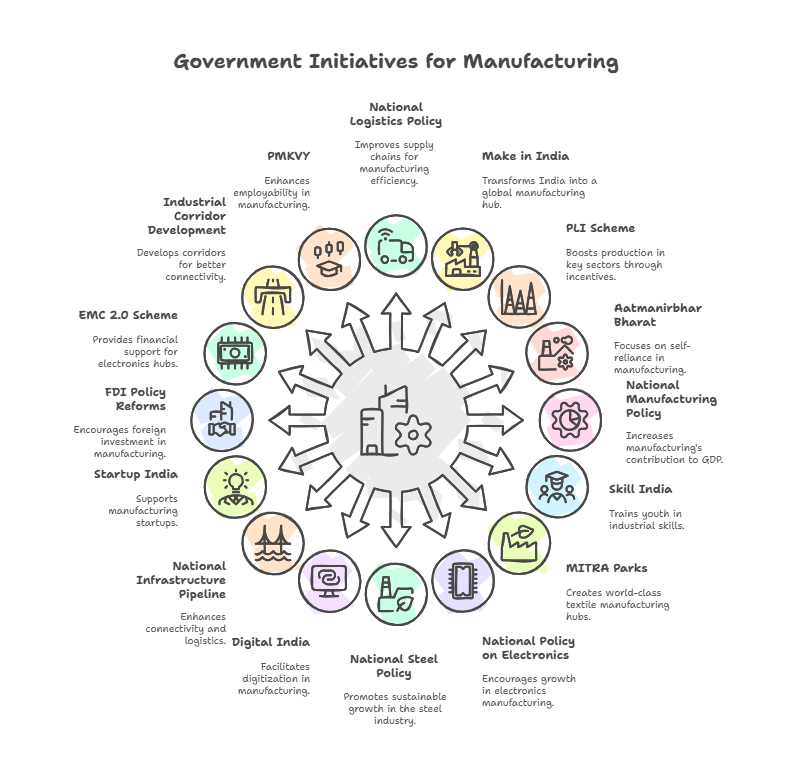

- Robust Government Initiatives: The government’s proactive policies, such as the "Make in India" initiative and the introduction of Production Linked Incentive Scheme, are actively fostering growth in key sectors.

- These policies are incentivizing global companies to establish production hubs in India, reducing import dependency.

- For instance, the PLI scheme has attracted major players like Apple, with smartphone exports surging by 42% in FY24, reaching Rs. 1.36 lakh crore (US$ 15.6 billion). These efforts are expected to boost India’s export-driven growth in the coming years.

- Digital Transformation in Manufacturing: The push towards Industry 4.0 is reshaping India's manufacturing landscape, with automation and digital tools driving efficiency.

- The increasing adoption of AI, IoT, and robotics is improving production rates and operational efficiency.

- India's manufacturing PMI for April 2025 stood at 58.2, signaling growth, driven by digital transformation.

- Moreover, India’s digital economy is projected to grow at twice the rate of the overall economy, further enhancing its global competitiveness.

- Growth in Exports and Market Diversification: India’s export landscape is diversifying, with a significant rise in non-petroleum goods, particularly in pharmaceuticals, electronics, and chemicals.

- The total export value reached USD 820.93 billion in FY25, with a notable contribution from the e-commerce and electronics sectors.

- Merchandise (goods) exports, excluding petroleum products, also reached an all-time high of USD 374.1 billion, representing a 6% increase, reflecting the success of India's manufacturing and export strategies under the PLI scheme.

- Emerging Sunrise Sectors: India is making substantial strides in emerging sectors like renewable energy components, medical devices, and semiconductors, positioning itself as a leader in these high-growth industries.

- The government’s focus on green energy and electronics manufacturing is beginning to yield results.

- For example, India’s semiconductor market is projected to reach USD 63 billion by 2026, as investments in chip manufacturing increase, spurred by initiatives like the Rs. 76,000 crore Semicon India program.

What are the Key Issues Associated with India’s Manufacturing Landscape?

- Land Acquisition Bottlenecks: The fragmented land records and unclear title issues continue to delay land acquisition for manufacturing facilities, hindering sector growth.

- The lack of a streamlined, unified land acquisition process leads to time-consuming disputes and regulatory challenges.

- Political consensus remains elusive, as seen in the failure of the 2015 land acquisition ordinance.

- A prominent example is the Hyderabad Future City project, where land acquired for one purpose (PharmaCity Project) is now facing legal challenges for being repurposed, causing significant delays and uncertainty for investors.

- Labour Reforms Delays: The slow and piecemeal implementation of India's new labor codes creates significant uncertainty for manufacturers.

- The reforms, passed by the central government, have yet to be fully implemented because labor is a concurrent subject, requiring states to frame and notify their own rules.

- For instance, West Bengal and Lakshadweep have not pre-published draft rules under any of the codes, while others like Delhi have only done so for the Code on Wages.

- This inconsistency across states hinders the creation of a seamless, unified national labor market, perpetuating the 'inspector raj' mentality that the reforms were meant to abolish.

- Infrastructure Gaps and Logistics Challenges Although India has made progress in digital and physical infrastructure, key logistics and transport inefficiencies remain major barriers.

- The lack of efficient and integrated infrastructure hampers the smooth movement of goods, affecting production timelines.

- The Economic Survey 2022-23 estimated India’s logistics costs at a high 14–18% of Gross Domestic Product (GDP).

- However, recent estimates by the National Council of Applied Economic Research (NCAER) place them lower, at 7.8–8.9% of GDP for 2022-23, reflecting significant improvement.

- Yet, they continue to remain slightly above the global benchmark of 8% of GDP.

- These logistics deficits raise manufacturing costs by 20-30%, limiting competitiveness against neighbors like Vietnam with superior systems.

- Skilled Labour Shortage: India's vast workforce is a demographic advantage, but its effectiveness is diminished by a severe skill mismatch.

- The lack of formal technical training and industry-specific skills, particularly in advanced manufacturing, makes it difficult for firms to adopt modern technologies and improve productivity.

- Only 4.1% of India's workforce (in the 15-59 age group) has formal technical training, a stark contrast to over 70% in countries like Germany and South Korea.

- In the automotive sector, for instance, the demand for skilled workers is high, but training programs remain insufficient to meet the growing requirements.

- Environmental Compliance Issues: Stricter environmental norms have increased compliance costs especially for high-pollution sectors like cement, chemicals, and textiles.

- The textile industry alone accounts for about 20% of India’s industrial water pollution, facing growing enforcement of wastewater treatment and Zero Liquid Discharge norms.

- For instance, in 2024, many small-scale dyeing units in Punjab’s Ludhiana cluster faced shutdowns due to failure to meet effluent standards, highlighting the compliance risk.

- Supply Chain Fragmentation and Over-dependence on Imports: India’s manufacturing remains vulnerable due to fragmented supply chains and heavy dependence on imported raw materials and components.

- This over-reliance exposes industries to global supply shocks and escalates input costs, undermining production stability.

- For example, 60-75% of electronic components for India’s domestic production are imported, causing input cost inflation amid supply chain disruption.

- Local supplier fragmentation further increases transaction costs and hampers scalability efforts.

- Potential Impacts of US Tariffs on Indian Manufacturing Exports: The recent imposition of steep tariffs by the US poses a significant threat to key Indian manufacturing sectors by raising the cost of Indian goods and making them less competitive.

- This is particularly impactful for labor-intensive industries that are highly dependent on the US market. The tariffs could lead to a loss of market share to competing nations.

- A recent analysis by the Indian Council for Research on International Economic Relations (ICRIER) found that almost 70% of Indian goods exports to the US-around $60.85 billion, are now exposed to a 50% tariff.

- This places labor-intensive sectors like textiles and apparel at a significant disadvantage

What Measures India Can Adopt to Enhance the Effectiveness and Efficiency of the Manufacturing Sector?

- Optimizing Land Use and Acquisition: India needs a National Industrial Land Bank 2.0 using GIS mapping and blockchain for title verification.

- Pre-cleared plug-and-play industrial corridors should be developed to cut legal disputes.

- A single-window clearance system must ensure quick approvals with transparent compensation.

- Rehabilitation packages should balance investor confidence with farmer welfare. Such reforms will make land access predictable and litigation-free.

- Streamlining Labor Regulations: Labour codes must move from paper to practice through a Centre–State coordination mechanism.

- Reform-linked fiscal incentives can push states to notify pending rules quickly.

- A Unified Labour Compliance Portal should digitise inspections and filings, curbing inspector raj. Worker representation must be protected to avoid a hire-and-fire perception. This balance will create a fair, flexible, and modern labour market.

- Enhancing Logistics and Connectivity: A National Integrated Logistics Grid under PM Gati Shakti linking roads, railways, ports, and air cargo is essential.

- Multimodal logistics parks and freight corridors can reduce delays and costs. AI-enabled tools for route optimisation, inventory tracking, and smart warehousing will modernise supply chains.

- Special focus is needed on hinterland connectivity for balanced industrial growth. Lower logistics costs will make Indian manufacturing globally competitive.

- Building a Future-Ready Workforce: A National Manufacturing Skills Mission should target Industry 4.0 skills like robotics, EV batteries, and green hydrogen. Dual apprenticeship models combining classroom learning with factory exposure will close the training gap.

- Large firms should be incentivised to run public–private skilling academies for MSME clusters.

- AI-driven platforms can link employers with skilled workers in real time. This will transform India’s workforce from abundant to truly competitive.

- Integrating Sustainability into Manufacturing: Instead of seeing green norms as hurdles, India should invest in Green Technology Parks with shared treatment plants and renewable units.

- A Green Credit System can reward firms for adopting circular economy practices. AI-driven monitoring systems must replace outdated manual inspections to reduce compliance costs.

- MSMEs should receive subsidies for clean technologies. This will align manufacturing growth with global sustainability benchmarks.

- Strengthening Domestic Supply Chains: India must build domestic component ecosystems in sectors like electronics, semiconductors, and pharma. MSMEs should be integrated into Global Value Chains (GVCs) through targeted supplier development programs.

- Tax incentives for backward integration can encourage domestic production of raw materials. Strategic reserves of key inputs will reduce vulnerability to global shocks.

- Strengthening local supply chains will boost resilience and reduce import dependence.

- Diversifying Global Market Access: India should diversify trade partnerships through Free Trade Agreements with EU, ASEAN, and Africa to cut US dependency.

- Export industries must adopt global quality certifications and branding for greater competitiveness.

- Export hubs should get policy support for scaling up high-value products. This proactive diversification will protect India’s market share globally.

- Digital Public Infrastructure for Manufacturing: Just as India transformed finance with UPI, a similar digital manufacturing stack can be created for production units.

- This may include interoperable platforms for supply chain traceability, machine data, and compliance monitoring. Such DPI can foster efficiency, transparency, and accountability.

Conclusion

India's manufacturing success depends on resolving the 3 Ms - Money (efficient land acquisition and financing), Materials (reliable supply chains), and Manpower (flexible labor policies through pending reforms). The convergence of global supply chain shifts and India's demographic advantage creates a narrow window that demands immediate political will. Such holistic reforms will not only enhance global competitiveness but also generate large-scale employment, driving inclusive and resilient economic growth in the coming decade.

|

Drishti Mains Question: Critically examine the key challenges facing India’s manufacturing sector in achieving its growth and employment potential. Discuss how policy reforms and infrastructure development can address these challenges to strengthen India’s position in the global manufacturing landscape. |

UPSC Civil Services Examination, Previous Year Questions (PYQs)

Prelims

Q. In the ‘Index of Eight Core Industries’, which one of the following is given the highest weight? (2015)

(a) Coal production

(b) Electricity generation

(c) Fertilizer production

(d) Steel production

Ans: (b)

Mains

Q.1 “Industrial growth rate has lagged behind in the overall growth of Gross-Domestic-Product(GDP) in the post-reform period” Give reasons. How far are the recent changes in Industrial Policy capable of increasing the industrial growth rate? (2017)

Q.2 Normally countries shift from agriculture to industry and then later to services, but India shifted directly from agriculture to services. What are the reasons for the huge growth of services vis-a-vis the industry in the country? Can India become a developed country without a strong industrial base? (2014)